Exhaust gas aftertreatment

// References

The following technologies were developed from concept to series production, mostly in leading positions:

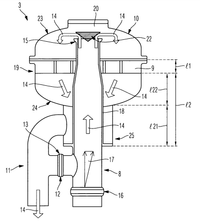

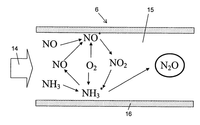

- Catalytic hydrolysis of urea

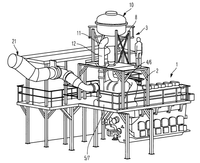

- SCR systems for trucks and ocean-going vessels (diesel, B100, HFO, gas, DF, MGO)

- High pressure SCR systems for low-speed two stroke engines

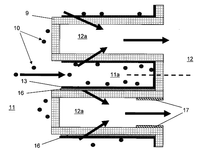

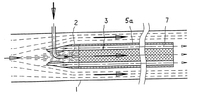

- Clog-free diesel particulate filter (awarded the German Environmental Prize)

- SCR coated particulate filter for trucks and passenger cars

- Sulfur resistent SCR particulate filter for ocean going vessels (EU- Hercules 2- project)

- Sulfur resistant catalytic methane oxidation (PtJ conference proceedings 2019 S. 27ff)

The tasks included

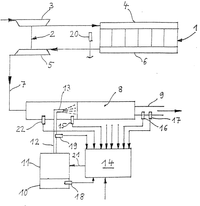

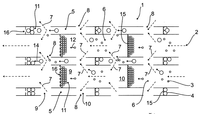

- Concept and process development

- Catalyst development and selection

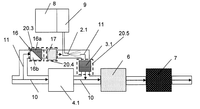

- Set-up of test facilities (laboratory and engine test bench) and supervision of engine and field tests

- Function development and calibration

- Supplier selection and management

- Certification process, in particular IMO Scheme B and US EPA

- Emissions acceptance by notified bodies (TÜV, DNV/GL, CCS, RINA, LR, BV etc.)

- Responsibility for emission complicance

- Risk assessments

- Documentation and failure trees

- Evaluation of engine and exhaust aftertreatment technologies with regard to their influence on greenhouse gas emissions (nitrous oxide and methane)

- Technology and component approvals

In addition to these developments, customer projects were also supported.

Furthermore, technology assessments, including engine tests, were carried out (e.g. desulphurisation technologies).